Roll-Wrapped Custom Carbon Fibre Tubes

Leaders in custom composite tubing

From our 45,000 Square foot facility in Rotorua, New Zealand, we've been custom-developing and producing world-class roll-wrapped carbon fibre tubes and sections for 90 years.

Our clients trust Kilwell Fibrelab to achieve the design and performance requirements they need to keep them ahead. From superyachts to aerospace, elite sport to defense, we partner with like-minded go-getters who push boundaries and lead from the front.

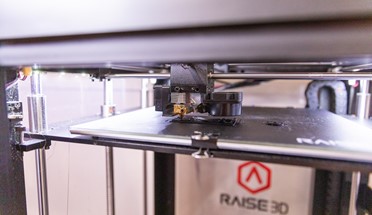

With temperature-controlled preparation rooms, custom-built curing ovens, 3D printing lab, CNC machining centre and an extensive finishing facility, there's not a lot we can't do.

Couple this with a dedicated team of 60 who bring multiple hundreds of years combined experience, and you'll get a sense of the scale and capability that Kilwell can offer.

The Roll-Wrapping Process

We often get asked, "what is the benefit of roll-wrapped carbon fibre tubes?"

There are many benefits but first and foremost, the roll-wrapping process lets our experts custom-design a vast array of properties into the components we develop. Couple this with cost-effective and replicable manufacturing at scale, and the benefits start to stack up fast.

The best way to think of it is that roll-wrapping builds layers up, rather than machining down from an extrusion or billet.

How can we help?

Keen to team up?

Let us know what you have in mind, and one of our team will get in touch to talk through your project and scope it with you. If you would like to share any drawings now, please do. Or, if you would prefer that we enter in an NDA first, we can make that happen quickly and easily.